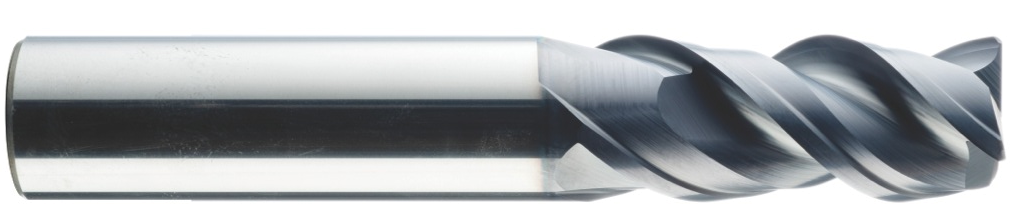

ENDMILLS (เอ็นมิลล์)

ดอกเอ็นมิลล์ (Endmills) หรือดอกกัดได้ถูกนำมาใช้ในงานอุตสาหกรรมอย่างกว้างขวาง เช่น อุตสาหกรรมผลิตชิ้นส่วนรถยนต์ อุตสาหกรรมผลิตชิ้นส่วนเครื่องบิน อุตสาหกรรมน้ำมัน เป็นต้น หน้าที่หลักของเอ็นมิลล์จะใช้สำหรับการกัดชิ้นงาน ให้เป็นรูปแบบต่างๆตามที่ต้องการ วัสดุที่นำมาใช้ผลิตดอกคาร์ไบด์เอ็นมิลล์จะมีคาร์ไบด์และโคบอลต์เป็นส่วนประกอบหลัก เพื่อเพิ่มความแข็งแรงและทนต่อการสึกหรอ การเลือกเอ็นมิลล์ที่เหมาะสมกับชิ้นงาน จะทำให้งานที่ได้ออกมามีคุณภาพดี ทั้งนี้จะขึ้นอยู่กับปัจจัยต่างๆ เช่น ขนาด ความยาวคมกัด จำนวนฟัน ความเร็วในการกัด อัตราการป้อน วัสดุชิ้นงาน เป็นต้น